- Sinutrain machine configuration with commissioning archive code#

- Sinutrain machine configuration with commissioning archive Offline#

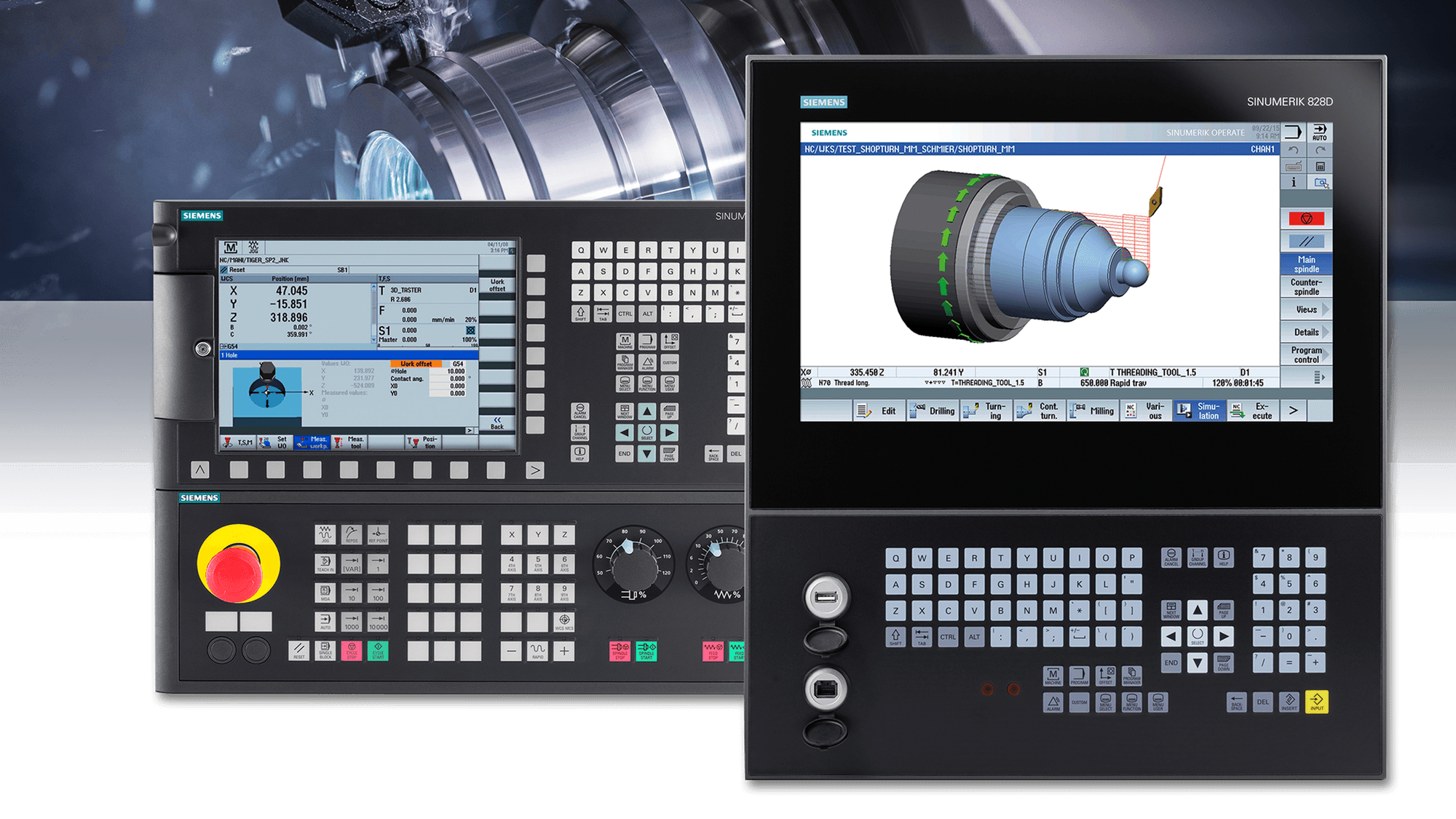

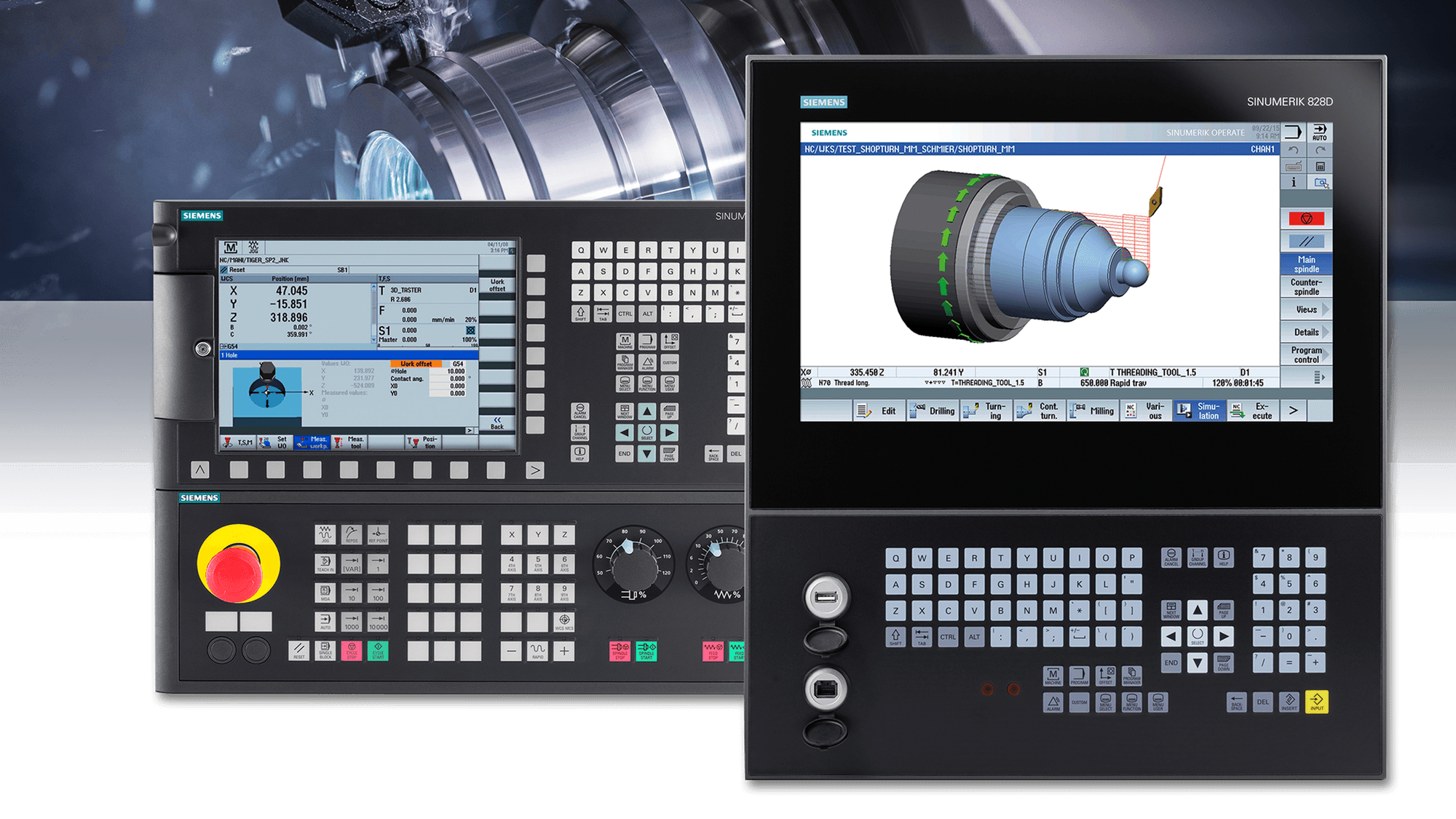

Production Execution/Machine Operation: Digitalization can benefit production execution (performing the planned machining operation) through Sinumerik control units and data analysis from Analyze MyPerformance.In keeping with its focus on digitalization, the company also offers a virtual TAC with webinars and virtual-training courses.

The new TAC offers learning opportunities such as classroom and online training for machine tool dealers, importers and end-users.

Sinutrain machine configuration with commissioning archive Offline#

Siemens also offers offline learning, which the company supports with its new Technical Application Center (TAC) at its Elk Grove Village facility, the opening of which coincided with the event at the DMDII. This phase also includes user training, for which the company offers SinuTrain CNC training software.

The company also enables virtual commissioning for machine builders to validate machining processes through its Mechatronics Concept Designer, Simit simulation software’s hardware-in-the-loop simulation, NX Virtual Machine and Run MyVNCK.

Sinutrain machine configuration with commissioning archive code#

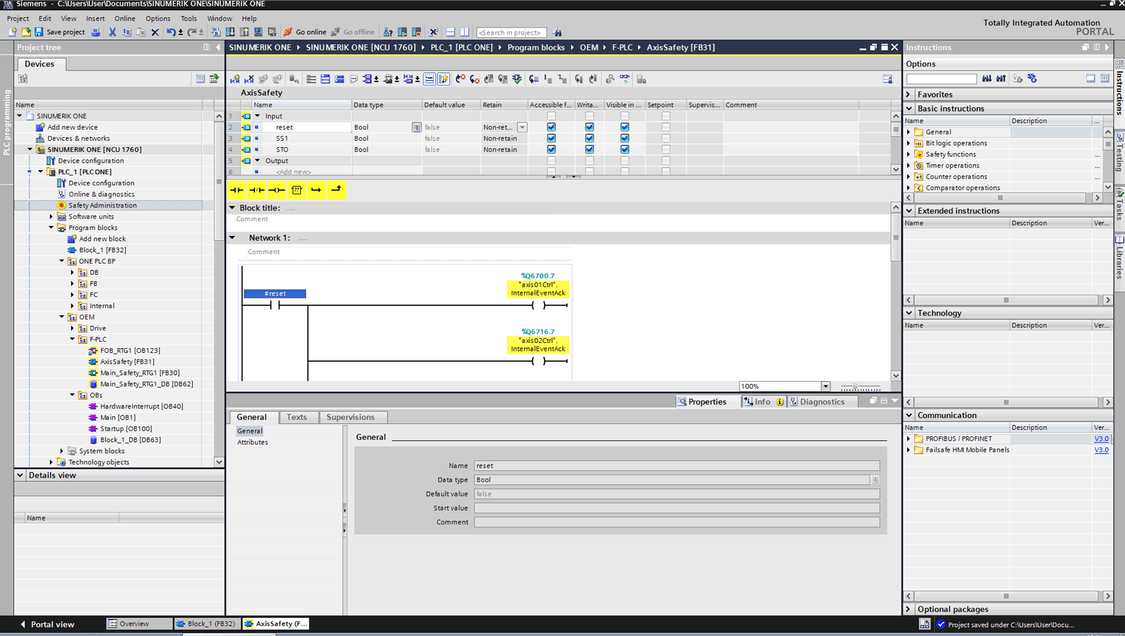

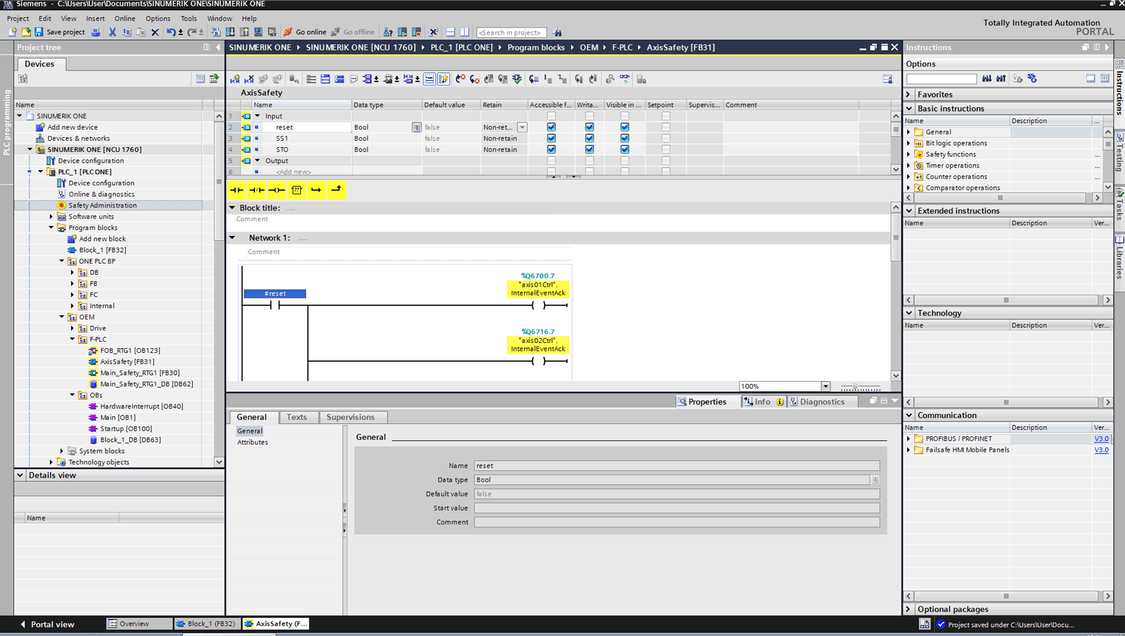

Production Engineering/Machine Commissioning: According to the company, this step for product manufacturers includes generating the NC code and validating the NC program, which can be done with the Virtual NC Controller Kernel (VNCK) embedded in the NX software. During this stage in machine engineering, machine builders have many considerations, including drives, such as Sinamics, as well as the drive’s design and configuration and programmable logic controller code generation via Sizer, Step 7 and the company’s Totally Integrated Automation (TIA) portal. For product manufacturers, this step can be accomplished digitally within the CAM software. Production Planning/Machine Engineering: Once the design or concept is finalized, manufacturers and builders need to plan and validate the procedures to make the product. This is digitally executed for product design using CAD/CAE/CAM software, such as Siemens’ NX, and for machine concepts with NX Mechatronics Concept Designer. Product Design/Machine Concept: Whether the user is making products or CNC machines, the first step is concept and design. Because the company’s customers are both product manufacturers and machine builders, it developed corresponding, parallel tracks for both perspectives. Siemens breaks down the value chain into five stages, and offers solutions for digitalization at each stage. According to the company, the key to staying competitive is a holistic approach that integrates the entire value chain, creating a “digital twin” of the value chain that exists in the virtual world.

0 kommentar(er)

0 kommentar(er)